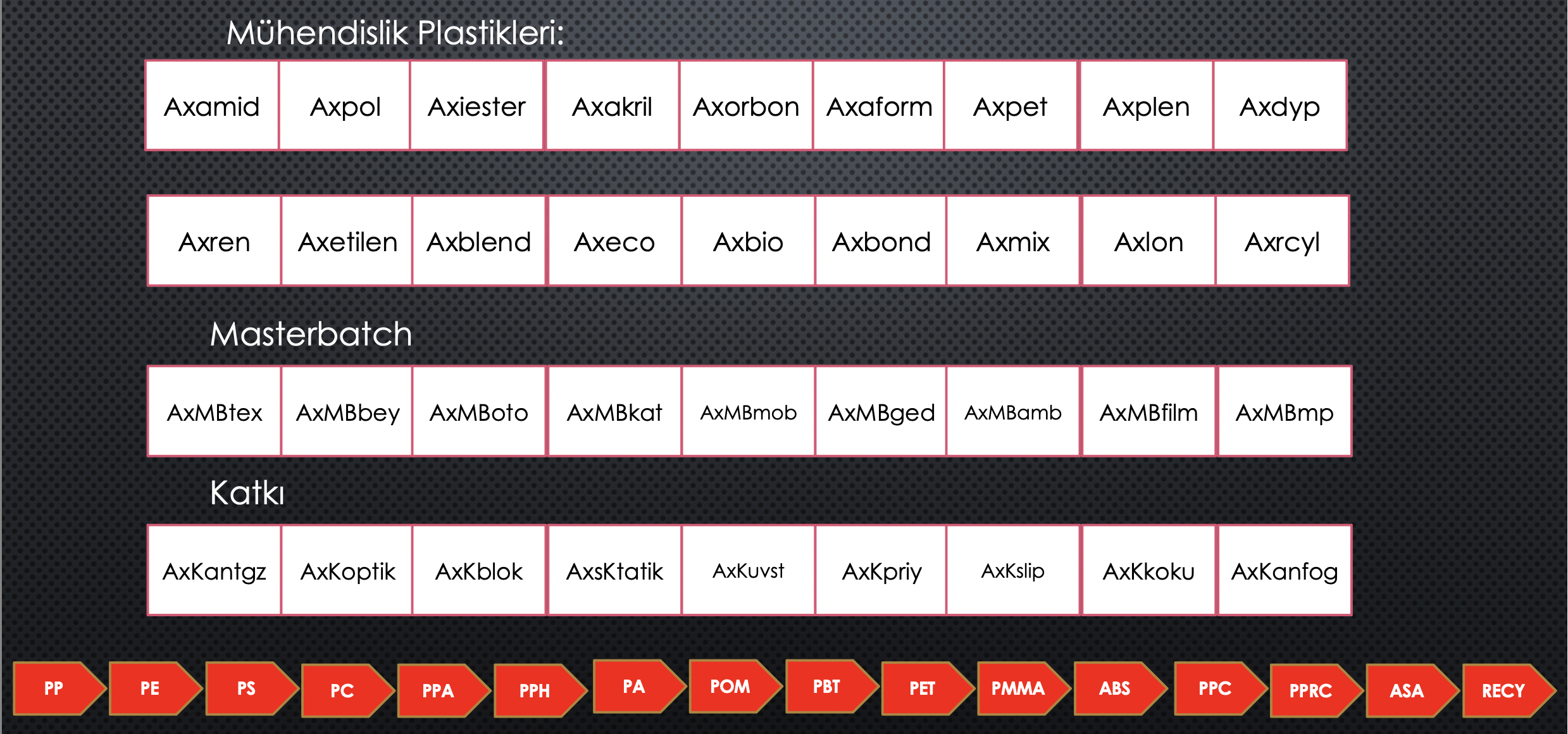

Engineering Plastics

Plastic

.

Application Areas

Axiamid

Polyamides constitute one of the most important groups of engineering plastics. It is a synthetic thermoplastic with high molar mass and crystallinity and low moisture activity. It is the best of the nylon types in terms of mechanical and physical properties. There is a wide range of products with various viscosity values, reinforced with glass fiber and similar fibers, rubberized, high thermal resistance, mineral filled and flame retardant, UV resistant. Polyamide products are used in many industrial applications due to their properties. PA6.6, which is known as the most durable plastics, also has the highest melting point. It has a semi-crystalline structure. The continuous use temperature of PA 6.6, which melts at 265 degrees, is 120 degrees. There is a wide range of products, including rubber, high thermal resistance, mineral filled and flame retardant, UV resistant. AXIS has leading expertise in the production of polyamide-based engineering plastics. We research, develop and produce our special products for our customers. We offer our wide range of products to our customers under the Axiamid brand to be used in different sectors.

» PA 6

» PA 66

» PA 12

» PA 46

» PA6 10. /PA6.12

» PPA

» PA +PP

» PA +ABS

» PBT/PET

» PBT

» PA+Biobase etc....

» Unfilled

» Glass Fiber Additive

» Glass Ball Additive

» Mineral (Talk-Calcite) Additive

» Fireproof (V0-V1-V2) Additive

» UV-Antioxidant-Antistatic Additive

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axpol

High performance engineering plastics meet high requirements in harsh environmental conditions. The operating temperature of these plastics is above 150°C and brings superior properties such as low friction, chemical resistance and high temperature resistance. AXIS Engineering Plastics has a variety of products consisting of polyphenyl sulfide (PPS) and polyphthalamide (PPA) compoundsGlass fiber - Glass ball - Carbon fiber - Aramid fiber - Heat stabilized - UV/light stabilized mineral filled and reinforced various ingredients create recipe ingredients in different formulations

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axiester

Polybutylene Terephthalate (PBT) is a partially crystalline saturated polyester. PBT is resistant to many chemicals at room temperature, including aliphatic hydrocarbons, gasoline, carbon tetrachloride, perchlorethylene, oils, fats, alcohols, glycols, esters, ethers, and diluted acids and bases. They are sensitive to strong bases. PBT is a crystalline, high molecular weight polymer with easy processing characteristics. Because the material crystallizes quickly, mold cycles are short and mold temperatures may be lower for many engineering plastics. PBT has strong dimensional stability and low moisture absorption.

In some areas, PBT can be used in place of other semi-crystalline thermoplastics (such as polypropylene, nylon, and polyacetal) due to the need to improve performanceGlass fiber, mineral filler and other additives cause PBT to become stronger; It changes the properties of the material and gives the following qualities to the PBT material:

Excellent rigidity and rigidity,

good mechanical strength,

Good coefficient of friction and fatigue resistance,

very good thermal stability,

High wear resistance,

good dimensional stability,

very good chemical resistance,

Excellent current and easy handling properties,

Low moisture absorption

Very good surface smoothness,

Less tendency to crack under load,

High heat resistance.

Halogen and halogen-free flame retardant composition,

UL94 V-2 or V-0 classifications (UL94 approved classes),

Hot wire burning index,

Hot wire flaming behavior (flameless),

Low smoke density

It is low toxic.

Axakril

ABS is a glossy material with a high styrene ratio as well as a high butadiene ratio. Ease of processing mainly styrene properties; It provides chemical resistance and improved surface hardness, butadiene is an amorphous polymer material that provides impact resistance. The best features of ABS compounds are high rigidity, high thermal deformation temperature, scratch resistance and low mold shrinkage rates. It can be made with various additives and formulations to increase impact resistance, deformation under temperature and heat resistance. Modifications made to increase impact resistance will minimally affect its properties when interacting with heat.

We invite you to explore our wealth for efficiency, cost, quality, innovation and sustainable products.

Axorbon

Polycarbonate is the best known amorphous material. It is preferred for its high light transmission properties and optical applications. Its structure is very sensitive to moisture, so it is very important to use special injection conditions. It has strong impact strength, high heat resistance and good dimensional stability. Although resistant to water, minerals and organic acids, it has the characteristics of partially soluble in aromatic hydrocarbons, fully soluble in chlorinated ones and soluble in strongly alkaline substances. It has good electrical properties. Products made from this raw material have a long service life and allow reuse.

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products

Axaform

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable productsAxpet

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axplen

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axdyp

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axren

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axetilen

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axblend

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axeco

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axbio

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axbond

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axmix

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axlon

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.

Axcyl

» Please contact our Technical department for product TDS and detailed information. We invite you to explore our richness for efficiency, cost, quality, innovation and sustainable products.